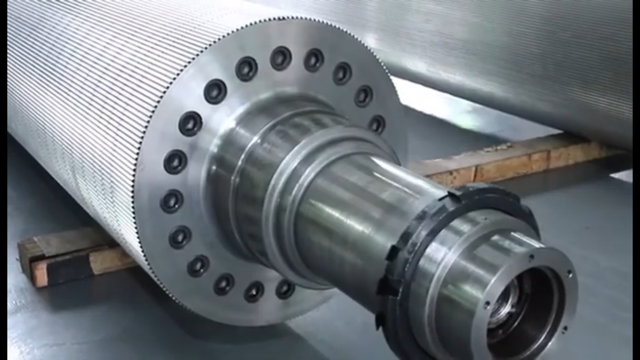

High Precision Steel Rollers

In the world of manufacturing and engineering, high-precision steel rollers are indispensable components that play a vital role in various applications. These rollers are not just any-ordinary parts; they are meticulously designed and customised to meet the specific requirements of customers, ensuring optimal performance and reliability.

Steel Rollers

High Precision Steel Rollers come in a plethora of sizes and surface finishes to cater to a wide range of industrial needs. The chrome finish is particularly popular for its corrosion resistance and smooth surface, which reduces friction and wear. On the other hand, compound rubber or composite coatings are sought after for their ability to absorb vibrations and noise, making them ideal for applications where quiet operation is essential.

Customisation of Steel Roller

The customisation of steel rollers extends beyond their physical attributes. Manufacturers often tailor-make these rollers to fit into specialised machinery, taking into account factors such as load capacity, speed, and environmental conditions. This level of customisation is crucial in industries where precision is paramount, such as in printing, packaging, and material handling.

One of the key aspects of high precision steel rollers is their manufacturing process. Precision engineering techniques are employed to ensure that each roller meets stringent quality standards. This includes the use of advanced materials, precision machining, and rigorous testing. The result is a product that not only performs exceptionally well but also boasts a long service life, reducing the need for frequent replacements and downtime.

The application of Steel Rollers

The application of high precision steel rollers is vast and varied. In conveyor systems, they are the backbone that keeps the belts moving smoothly. In the printing industry, they ensure that paper is fed through the presses accurately. In the world of cash handling and packaging, they are responsible for the precise movement and handling of delicate items.

Steel cylindrical objects

It’s clear that high precision steel rollers are more than just simple cylindrical objects; they are the culmination of advanced engineering and manufacturing expertise. They are a testament to the importance of precision in the industrial world, where even the smallest components can have a significant impact on the efficiency and success of operations.

For those looking to procure high precision steel rollers, it’s essential to partner with reputable suppliers and manufacturers who can provide not only the product itself but also the expertise and support required to integrate these components seamlessly into existing systems.

Crafted with Precision and Designed

Companies like Avanti Conveyors or Martin & Taylor are great examples of suppliers that offer a wide range of conveyor rollers, or high precision steel rollers crafted with precision and designed to meet various industrial demands. Many of these rollers may have a special surface finish that meets high performance and longer life for different applications in numerous industries.

In conclusion

High precision steel rollers are critical to the smooth operation of countless industrial applications. Their design, manufacturing, and application speak volumes about the intricate world of precision engineering and the relentless pursuit of perfection in the industrial sector.

Whether it’s for a conveyor system, a printing press, a single facer in corrugators, or for paper or solid board laminators or high speed sheeters. These are among some of the many applications that use high precision steel rollers in their machinery. These rollers ensure that the wheels of industry keep turning with precision and efficiency.